The selection of appropriate materials is crucial in manufacturing metal parts. Factors such as conductivity, strength, durability, and cost must be considered. For example, materials like steel, aluminum, copper, and various alloys are commonly used in the production of electrical and auto parts.

Raw materials need to be processed and prepared for manufacturing. This may involve cutting, casting, forging, or extruding the metal into the desired shapes and sizes. Precision in material preparation is essential to ensure the final product meets the required specifications.

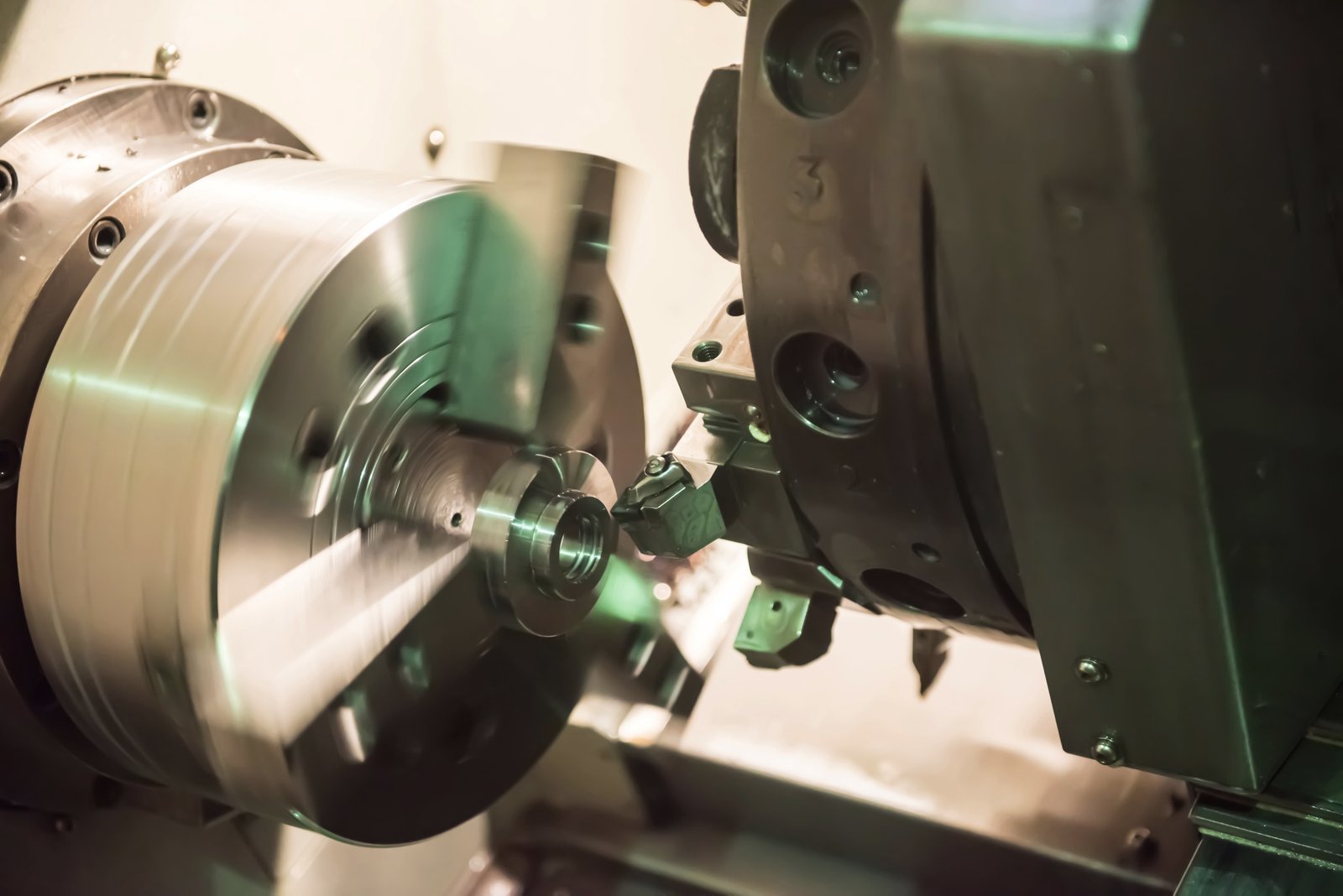

This step involves using various machining processes such as turning, milling, drilling, and grinding to shape the metal into the final product. CNC (Computer Numerical Control) machines are often employed to achieve high precision and consistency in the manufacturing process.

Metal parts may undergo forming processes like stamping, bending, or deep drawing to achieve specific shapes. Forming can be a critical step in creating complex structures or achieving tight tolerances.

Throughout the manufacturing process, quality control is essential to identify and rectify any defects. This includes visual inspections, measurements, and non-destructive testing techniques to ensure the parts meet the specified standards.

Maintaining traceability of materials and processes is crucial for quality assurance. This involves documenting the source of materials, production steps, and any testing or inspections performed. It helps in identifying and addressing issues if they arise and ensures accountability in the manufacturing process.

Implementing continuous improvement practices, such as Six Sigma or Lean Manufacturing, helps in optimizing processes, reducing waste, and enhancing overall efficiency. Regularly reviewing and refining manufacturing procedures can lead to better quality products and cost savings.